Delta Band Saw | Retrofit a Grizzly Riser Block

Did the Grizzly Riser Block fit my older Delta? ABSOLUTELY But not without some modification/fabrication

I recently picked up an older Delta Band Saw (model# 28-274 from the mid 90’s) off Craigslist for $200. Sweet deal but I really wanted to re-saw lumber greater than 6″ so I looked into a riser kit. I quickly found that the kits for the older Delta band saws are around $200 while the Grizzly (Model H3051) sells one for $89.95. I read forums and found some confusion around this so I thought I may be useful to some if I documented it here on my blog. Virtually every part required modification and I had to fabricate my own guide post from scratch.

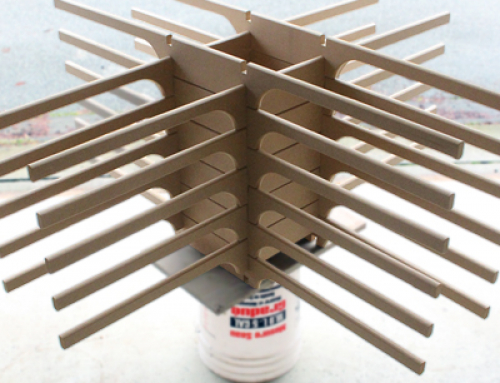

The kit comes with:

- Riser Block and Large Bolt

- Inner Blade Guard

- Outer Blade Guard

- 3/8″ x 105″ x 6 TPI Blade

- Guide Post

The first order of business it to deal with the pins which align the upper and lower cast iron sections of the saw. The Delta pins can be easily removed with pliers. I chose to leave the bottom pins out which gave me complete control later when I was aligning the 14″ upper and lower wheels.

The new Grizzly riser block however comes with it own pins which cannot be removed (easily) and do not line up with the Delta upper cast iron section. So we must drill the cast upper arm to accept the new riser block. I used a cardboard template and pressed it into to the new riser block to transfer the pin locations. I then taped it to the cast upper, center punched, and drilled it.

Installation of the riser block is just as the manual (and better video) explain it to be so I won’t cover it here.

Now the guide post on my Delta is circular but 15/16″ in diameter and the kit’s guide post is 7/8″. NOT COMPATIBLE, very unstable when mounted as-is and the bottom portion wouldn’t allow for adjustment of the blade guide. I have access to a small metal lathe and have never used one before, I produced one from 1 1/8″ stock I had on hand and it worked out great. If you don’t have a lathe or a machinist friend, than this may blow the budget to have someone fabricate it for you.

So definitely measure your guide post. Knowing the info above, you can make an informed decision on whether you can make this kit work for your saw. Apparently older Deltas had 7/8″ hex guide posts so that may work unmodified.

Thank you for stopping by!

Nice write-up!…thanks for sharing

Band saws are great for making an arc cut in wide planks of wood. I built a curved fence using the Jet Band Saw that my friend had. I have been curious about the other ones and appreciate good comprehensive reviews on the fine points of these various models.

The saws with the 7/8 hole also have a 15/16 hole concentric to the heck Are shim from sheet metal or 3/4 type Monday copper tubing will make it work. I drilled the block on the ones I have installed. Only an extra 10 minutes to make it more stable in the end.

Hey Daniel (or others), I think what you are saying is that you can easily shim with copper pipe or sheet metal. Is that right? It seems like the only difficult part of this operation is fabricating the guide poll (if you don’t have a machinist friend). If a shim from cutting a 1” pipe would work, that would make this doable. I did see in another post that a person finding a stock piece of 15/16 stainless steel wasn’t that hard to find, so that may be an option.